Service & Reparatur

Als zertifizierter Servicepartner sorgen wir weltweit für den zuverlässigen Betrieb Ihrer Hydraulikanlagen. Regelmäßige Pflege- und Wartungsarbeiten durch unsere fachkundigen Mitarbeiter sorgen für eine jahrelange, reibungslose Einsatzdauer Ihrer Anlagen. Auch für Reparaturen oder die Erweiterung Ihrer Anlagen sind wir mit unserem aktuellen technischen Know-how kompetent für Sie da.

- eigenes Ersatzteillager

- Servicefahrzeuge

Reparatur – Field Service

- Fehlerdiagnose

- Austausch Hydraulikstempel und Hydraulikzylinder

- Pumpenersatz

- Elektromotoren und elektrische Bauteile

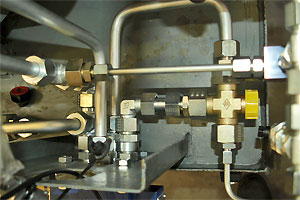

- Rohr- und Schlauchreparaturen

- Ventilaustausch

- Leistungsanpassung an neuen Bedarf z. B. von Pressen bei Produktwechsel

Reparatur

- Zylinder

- Hydraulikstempel

- Motoren

- Pumpen

- Ventile

- Elektrotechnik

- ... und alles andere einer Hydraulikanlage

Ölservice, Reinigung & Konservierung

- Spülen der Aggregate und Rohrsysteme (maximaler Volumenstrom 750 l/min)

- Filterwechsel

- Ölwechsel

- Ölanalyse/Fluidservice (Laboruntersuchung)

- Partikel (Verunreinigung, Verschmutzungsgrad)

- Viskosität

- chemische Zusammensetzung

- Ölanalyse/Fluidservice (Laboruntersuchung)

- fachgerechte Entsorgung Altöl

Prüfung von Anlagen & Behältern

- Prüfung von Druckspeicheranlagen gemäß Betriebssicherheitsverordnung § 14 (2)/§ 15 (2) in Zusammenarbeit mit dem TÜV

- Sicherheitsprüfung

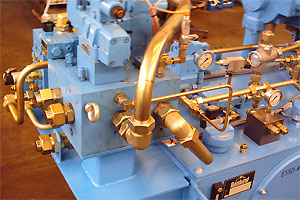

- Dichtigkeitsprüfung auf eigenem Prüffeld

- Funktionsprüfung

Anlagenretrofit

In vielen Fällen lassen sich alte Anlagen optimieren und mit modernen Komponenten effizienter und sicher betreiben. Als einer der ersten Partner von „Bosch Hydraulik + Pneumatik“ (1957) können wir auf einen umfangreichen Bestand an Datenblättern von alten Anlagen zugreifen, um diese kostengünstig zu modernisieren.

SPS-Fernwartungskoffer

Unser SPS-Fernwartungskoffer ermöglicht unseren Spezialisten den Service von Anlagen ohne Präsenz vor Ort.

Bei Bedarf versenden wir unseren SPS-Fernwartungskoffer zum Einsatzort, das spart Kosten und wertvolle Zeit.

Über eine sichere Verbindung können unsere Spezialisten die Funktionen der Anlage analysieren und optimieren sowie erforderliche Maßnahmen einleiten.

Lesen Sie mehr zu unserem neuen SPS-Fernwartungskoffer.

Prüfung von Hydraulikanlagen und Komponenten

Vor der ersten Inbetriebsetzung sowie in wiederkehrenden Abständen müssen Hydraulikanlagen und ihre Komponenten

(Druckspeicher, Sicherheitsventile, Hydraulikschläuche) geprüft werden.

Für die Einhaltung der gesetzlich vorgegebenen Prüfungen stehen wir mit unserer langjährigen Erfahrung und unserem Know-how

begleitend zur Verfügung.

Lesen Sie mehr zum Thema „Prüfpflichten Hydraulikanlagen“.

Jetzt auch Prüfung ohne Ausbau der Speicher möglich.

Erfahren sie mehr auf „www.druckspeicher.info“.

Kompetente Lieferanten/Partner

Wir sind unter anderem Service- und Vertriebspartner von Bosch Rexroth und von MOOG.

Durch diese Kooperationen können wir unseren Kunden einen erstklassigen Rundumservice aus einer Hand bieten.

Erfahren Sie mehr auf „Wir über uns“!

Mietaggregate

Für geringe Ausfallzeiten stellen wir Ihnen während der Reparaturdauer nach Möglichkeit ein Mietaggregat zur Verfügung. Welche Geräte und Anlagen aktuell verfügbar sind, entnehmen Sie bitte unserer Seite „Mietaggregate/-geräte“!

Für unsere Kunden sind weltweit im Einsatz – lesen Sie mehr auf Referenzen!